About half of all plastic used is polyethylene (LDPE, HDPE) or polypropylene (PP). At the end of its lifecycle, this plastic ends up in the environment or with a waste processor, where it is recycled, incinerated, or dumped.

Producing conventional plastics is an energy-intensive process and incinerating plastics has a negative impact on the environment, using fossil fuels and generating CO2 emissions.

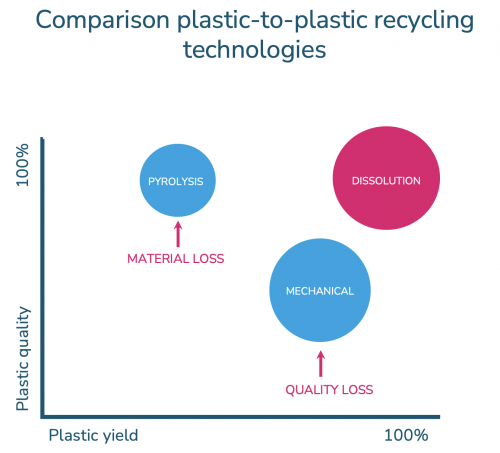

Besides, current recycling methods often do not produce the desired results. Mechanical recycling, for example, often does not meet the required plastic quality. Additionally, chemical recycling technologies that run via a (naphtha) cracker are low in terms of mass and energy efficiency.

Below you will find our mini lecture about the advantages and disadvantages of the various recycling techniques.

Would you like more information about SPEX's recycling technology?

Please contact us. We are happy to help you.

| Cookie | Duur | Omschrijving |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duur | Omschrijving |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_X73X5YES1T | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_215890515_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |